Bridge wheel washers

For years, the Bridge models have been the premium wheel washers for special vehicles and challenging locations in mining, raw materials or industry. The Bridge wheel washers are also the ideal choice for cleaning military vehicles. The wheel washers are available as painted steel or hot-dip galvanised constructions, where length, width, number of nozzles and pump capacity can all be tailored to your personal requirements.

An investment in a Bridge premium wheel washer is a long-term choice. Designed for demanding industries, these wheel washers combine unparalleled performance with an exceptionally long service life. Save on maintenance costs and increase efficiency with a system that is built to exceed the highest standards. Choose top performance, choose durability, choose the best!

The Bridge models are the ultimate wheel washers for when you expect the best and only the best. Discover why below.

Water recycling tanks

Modular Painted Steel Water Tanks: Tailored Solutions with Advanced Sludge Removal

In the realm of water storage solutions, flexibility, and efficiency are paramount. That’s why our modular painted steel water tanks have become the go-to choice for businesses seeking adaptable and innovative options. With the optional extra-large scraper conveyor for sludge removal, our tanks offer a superior solution for maintaining water quality. Here’s why you should consider them:

Size Customization: Our water tanks can be designed with your specific needs in mind. We offer a flexible and scalable solutions, allowing you to tailor the tank’s capacity and configuration to your requirements. Whether you need a small system for a compact space or a large-scale storage solution, our design team creates a water storage solution to your unique needs.

Advanced Sludge Removal with Extra-Large Scraper Conveyor: One of the standout features of our tanks is the optional extra-large scraper conveyor system – the widest in the wheel washing world. This unique equipment streamlines the removal of sludge and sediment, ensuring that time-consuming manual sludge removal isn’t necessary. The scraper conveyor’s wide size enhances its efficiency, allowing for uncomparable sludge evacuation capacity.

Uncompromised Durability: Built from high-quality painted steel, our tanks are engineered to withstand the test of time and environmental challenges. The durable construction ensures long-lasting performance, making them a reliable choice for various industries and applications.

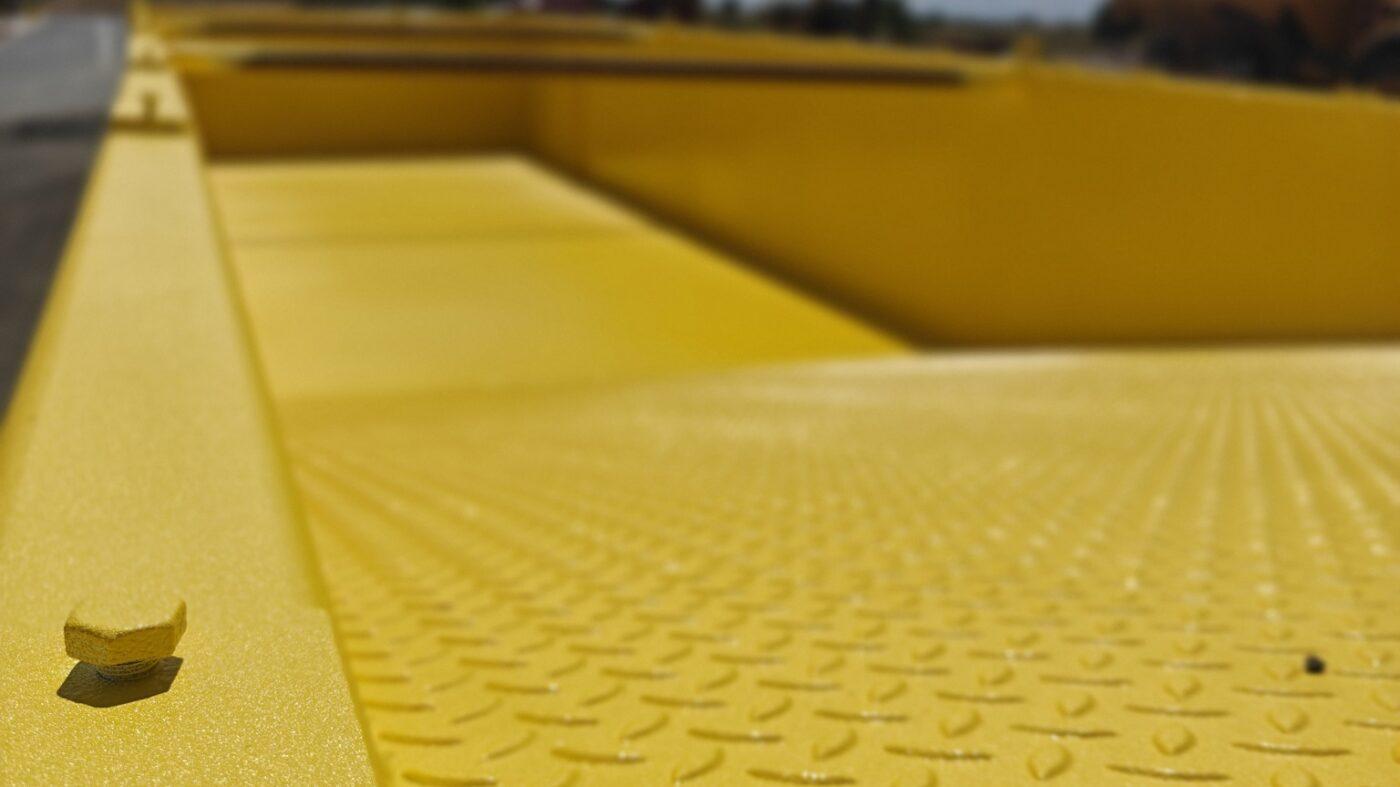

Tailor made frame

When it comes to tackling the toughest cleaning challenges, our premium Bridge wheel washer frame is the undisputed leader. Crafted from thick steel and designed for years of heavy-duty use, the Bridge units boast hundreds of nozzles from all angles, setting new standards for cleaning capacity.

Built to Survive and Thrive: Our Bridge wheel washer frames are a workhorse built to last. Crafted from thick, high-quality steel, it’s engineered to withstand the most challenging conditions and usage demands over a maximal lifespan.

Elite cleaning capacity: When it comes to cleaning power, the frame is loaded with an incomparably number of high-pressure nozzles, strategically positioned from all angles. This ensures thorough and efficient cleaning, leaving no wheelsurface untouched. All frame parts are laser cut with nozzles in 30° angle to prevent water splashing into windows

Extreme Length Options: Looking for a sturdy wheel washer despite low dirt levels or dragging kneep deep in mud? The Bridge frame is available in lengths ranging from four to twelve meters for those facing the most extreme conditions.

Customization at Your Fingertips: Whether you’re working with hefty payloads or extreme wide vehicles, no matter the challenge provided, any frame can be custom tailored to meet your specific requirements. Ensuring you have the wheel washer you need.

GWC Water treatment system

The GWC water treatment unit is an advanced filtration solution designed for the most demanding sites optimizing the performance of wheel wash systems. By effectively removing dirt, sediment and contaminants from the wash water. The GWC ensures longer system lifespan, fewer maintenance issues and most importantly superior cleaning results.

Moreover, installing a GWC water treatment unit is a highly economical choice as its performance is comparable to 100 m³ of settlement tanks at a fraction of the cost.

Key Benefits of the GWC System:

✔ Prevents Clogged Spray Nozzles – The advanced filtration system removes fine particles, reducing blockages and ensuring consistent water flow.

✔ Cleaner Vehicles & Equipment – Treated water enhances washing efficiency by allowing higher washing pressure. Leaving wheels and chassis spotless when exiting the wheel washer

✔ Limited surface area – As the GWC is a vertical tank, the required surface area is no more than 4 m². This allows for ultimate decantation in the smallest possible space.

✔ Low Maintenance – With fewer clogs and sediment buildup, downtime of your wheel washing unit is minimized.

✔ Economical option – By filtering through centrifugal force in a vertical tank decantation is performed by a comparatively small plant. This makes it much more economical than series of water tanks which are expensive and difficult to clean.

The GWC seamlessly integrates with wheel wash installations, ensuring optimal performance in high traffic construction sites, mining operations and industrial facilities. Its robust design handles heavy dirt loads while keeping spray nozzles clear for uninterrupted operation.

Are you experiencing dirty water and continious blocking of nozzles? Upgrade your wheel wash system with GWC and experience cleaner results, lower costs, and hassle-free maintenance!